TBM selection under specific scenarios

- Si Shen

- Apr 12, 2022

- 2 min read

This previous blog explained the general principles of TBM selection for a tunnelling project. This post looks in more details at the pros and cons between EPB TBMs and slurry TBMs under specific scenarios of consideration.

Mixed face tunnelling

Usually one TBM is specifically designed to target one type of ground. However, due to route constraints, or in the case of large diameter TBMs, considerable mixed face conditions (variable layers/strata encountered at the tunnelling face simultaneously) may be inevitable. Even if a homogenous route is planned, the excavation may uncover unexpected ground conditions. In simpler terms, you don’t always get what you want at the tunnelling face. Different layers could bear different face pressure. The pressure control of EPB TBM is less accurate compared to slurry, since it mostly relies on the muck itself to balance the pressure, which tends to be variable. The balancing pressure of a slurry TBM better follows a hydraulic gradient thanks to the presence of bentonite fluid.

Low cover tunnelling:

When the EPB first drill into the ground, it is likely to have the lowest cover of ground along its entire route. Low-cover tunnelling is a risky operation, as the cover may not be strong/stiff enough to withstand the gigantic power of the TBM. EPB TBM has advantages in dealing with launching with low cover. Because it relies on the muck to balance the face pressure, at the top of the TBM cutter head, the pressure is comparatively lower than a slurry TBM. Lower pressure at the top significantly reduces the risk of ground heave, or much worse, blow-out failures.

High water pressure:

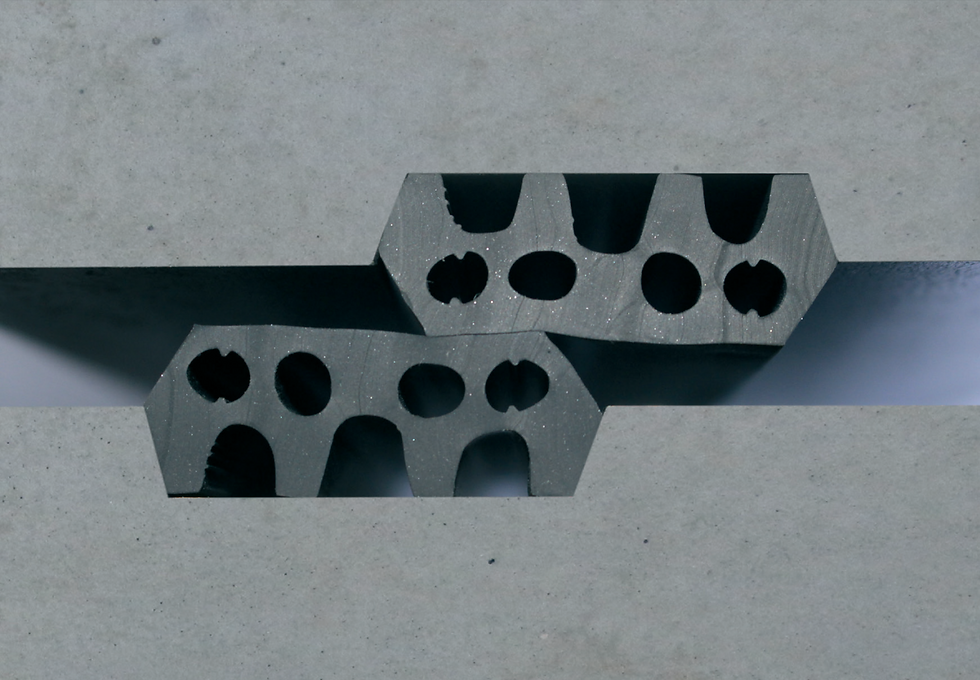

Slurry TBM wins out with advantages in dealing with high water pressure. High water pressures in EPB may lead to ‘piping’ effects (i.e. water rushing in) in the screw, especially when dealing with coarse grained soils The screw conveyor used in the EPB has the function of reducing water pressure as it extends out and upwards, but there is a limit to how much it can do. Under high water pressure, the EPB machine would require extremely long screws, or perhaps doubling up of the system.

Compact site space

Some sites, especially in urban areas, available space is as precious as gold. In some cases, the available space is a given. EPB TBM generally has less requirement in site space compared to slurry TBM. Slurry TBM requires large surface space for the production and storage of slurry, and separation plant for the recovering the slurry from the muck.

Minimising face interventions

Some face interventions are particularly costly and hazardous (e.g. under hyperbaric conditions) and therefore the frequency and duration of face intervention (e.g. for replacing cutters) needs to be minimised. Slurry TBM comparatively has less face maintenance requirements. EPB uses muck to balance face pressure whereas slurry TBM uses bentonite. Muck is a lot more ‘grindy’ than the bentonite, i.e. with much higher shear capacity. Therefore the power requirement for EPB tends to be higher than slurry TBM, and therefore causes more cutter wear and more frequent face intervention is required. Slurry TBM is also easier to ‘restart’ after an intervention, thanks to its air bubble that regulates the face pressure.

Comments