TBM thrust estimation

- Si Shen

- Mar 4

- 2 min read

A TBM advances by thrusting against the built segments through an array of cylinders around the circumference. This thrust is a design case for the tunnel segments as it can cause cracks by splitting or spalling. This thrust can be estimated, by incorporating the following contributing factors:

Support against face pressure. A main function of the TBM in soft ground condition is to balance the pressure at the face to prevent tunnel collapse and limit ground settlement. The load transfer path goes from the ground into the TBM bulkhead and then into the thrust cylinders that serve as bearings against the built tunnel segments.

Towing the TBM backups. The TBM backups do not power themselves but are trailers on wheels towed by the head. Due to the self weight, there are friction forces and possibly an additional small component of drag from inclination of the tunnel alignment.

Ground friction on shield skin. The ground surrounding the shield tends to close in after excavation which generates friction. The TBM needs to overcome this friction in order to move forward. The bigger size the soil particles are, the higher friction there is. The friction coefficient goes from about 0.2 in Clay to 0.5 in Gravel. Injecting bentonite can provide lubrication and reduce friction coefficient to somewhere between 0.1 and 0.2.

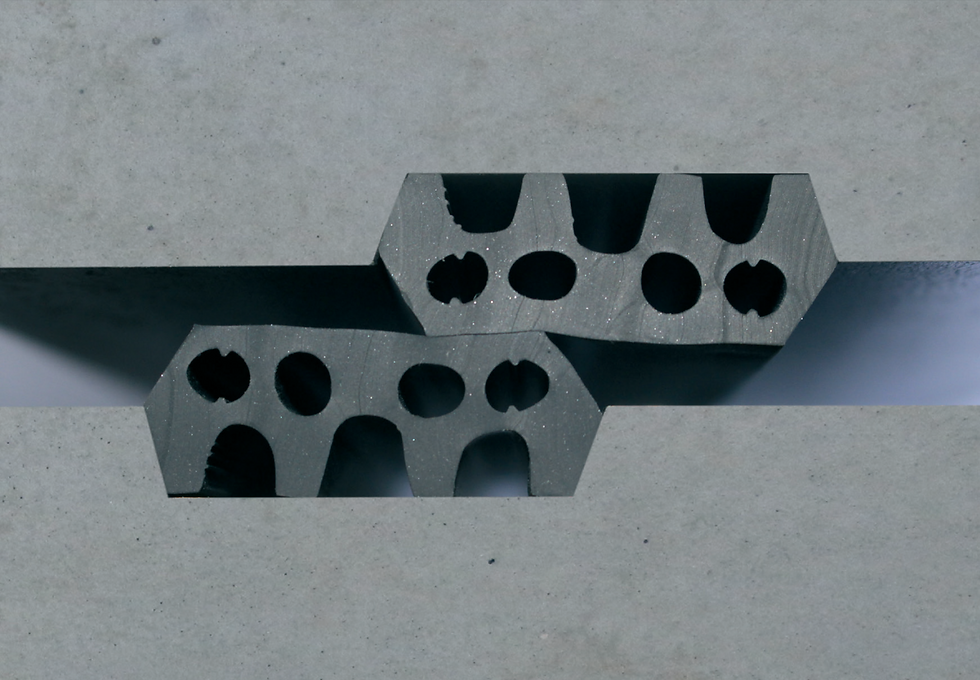

Thrust required for advancing excavation. The cutting tools on the TBM cutterhead need to be pressed into the ground for them to be effective in excavation. This is particularly significant for advancing in rock conditions. The cutter disks used in hard rocks work on the basis of pushing the disk blade into the rock hard enough to cause local failures and crumble the rocks. There is a threshold value to enable these local failures.

Thrust distribution for steering the alignment. The TBM steers and turns itself by pushing harder on one side than the other – it turns away from the higher thrust side.

The values above can not be calculated exactly. Therefore in addition, there is usually an empirical margin allowed on top of the sum of all the above.

Experience shows that the thrust of a TBM is approximately related to the tunnel diameter to the power of 2.

Comments